Tesla shows the way: How gigapresses are changing car manufacturing

Summary

New Manufacturing

Instead of many individual body parts, gigantic die-casting machines are used to cast and press rear and front parts of

Tesla is thus able to achieve high profit margins and massively lower the prices for its e-cars, as happened recently.

The front and rear cars pressed in one pass replace around 60 individual parts. The vehicle underbodies are then assembled with the battery packs to form chassis. The Giga presses save 300 robots per element on the Model Y, which would otherwise have to assemble smaller parts for the front and rear frames. This can reduce costs by up to 40 per cent.

IDRA

which was taken over by the Chinese LK Industries in 2008, has been developing these monstrous machines since 2016. The latest and largest so far has the dimensions of a small house and a clamping force of 9000 tonnes. The press jaws are as big as delivery vans.

Traditional

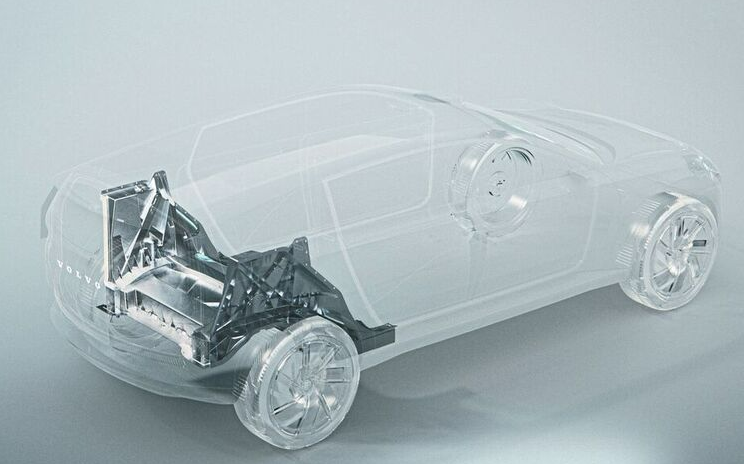

Pic: Volvo

Traditional carmakers have already largely automated body construction. In view of rising raw material prices, the pressure for further production advances is now increasing. That is why carmakers like Toyota, General Motors, Hyundai, Volvo Cars and the Chinese electric vehicle start-up Nio are turning to manufacturers like IDRA. Volkswagen, however, has refrained from using the technology in its flagship Trinity after first considering it. BMW has so far shown no interest.

Quality risks

A single error in...

Like what you see?

Then log-in to unlock all the content or become a member of Carmunication today!

Written by Carmupedia Editorial Office

You might also be interested in

Your member panel

From here you have full control over your profile